Every day, we are involved in the continuous development of hardware and programming of the robots to constantly improve our applications in terms of flexibility, ease-of-use and programming speed. We also customise software solutions based on individual requirements to make our customers more competitive.

A team of designers which implements functional solutions aimed at optimising production processes and achieving the best aesthetic and functional results. Experience, combined with the ongoing research for new technologies and relevant innovative applications, has resulted in the custom hardware solutions for different industrial sectors.

— Foundry

Custom Project

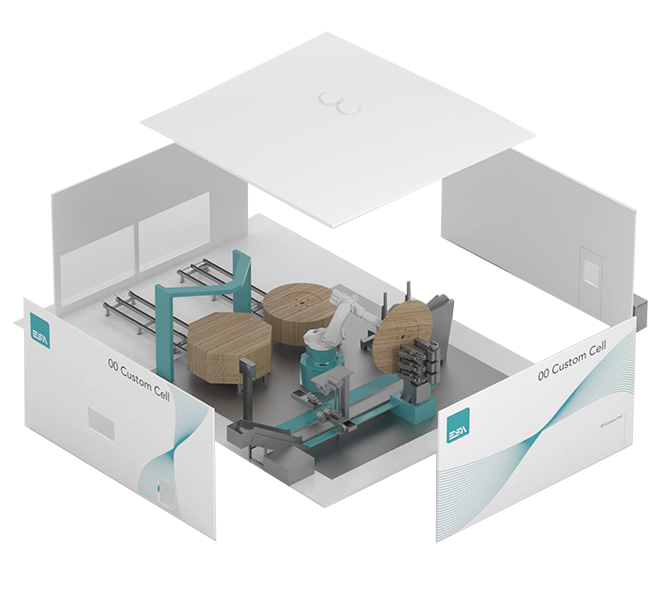

We design and develop robotic solutions for the automation of industrial processes in general: tending machine, pick & place, handling and many other applications.

Discover More